PTFE Sleeves Multi Core/Pair Cable Manufacturer in India

PTFE Insulated Multi-core Cables are produced using a synthetic fluoropolymer, and they are used in virtually all electrical, electronic, and technical fields. Particularly for applications requiring high temperature and high frequency, PTFE-insulated multicore wire is necessary. The PTFE sleeves have excellent thermal properties. The FLU-TEF WIRES & CABLES PVT. LTD. guarantees that these sleeves won't separate under any pressure. Certified PTFE wire Sleeving display reduced embrittlement, has good mechanical properties, are highly dielectric and chemical resistant, and are extremely flame resistant. Since many wiring connections must be employed in such applications, they are widely utilised in scientific instruments, electric heaters, transformers, and motors. For these purposes, a single cable with a number of cores is ideal.

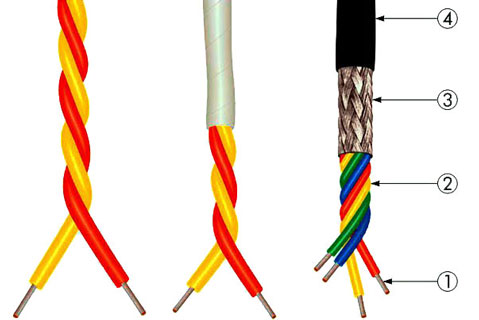

Construction :

- 1Conductor

- 2Core insulation : Extruded or tape wrapped PTFE

- 3Braided shield

- 4Jacket : PTFE tape wrapped & Fused.

Colour : The colour range of PTFE Jacket Black, Green, White, Blue, Grey, Red, Yellow, Brown, Orange, violet.

Characteristics of PTFE Sleeves :

- To precisely match customer demands, PTFE multi-core cables are produced in accordance with ANSI/NEMA WC 27500/JSS 51038 specifications for use in aerospace and industrial electrical applications.

- According to JSS 51034/MIL-W-16878/NEMA HP 3, the cable primary is made of PTFE wire.

- The cable is available in sizes ranging from single wire and has all the distinct electrical and mechanical qualities of PTFE. 84 maximum pairs of twisted, screened, jacketed, or both, depending on the application, screened or/and jacketed cable.

- The PTFE Sleeve Joint is incredibly adaptable. These joints have high conductivity and are highly robust.

- These sleeves' anti-stick qualities prevent the growth of sediments and fungi.

- The best materials were used in the design of the PTFE Sleeves. By using these insulated sleeves, you can prevent equipment damage and leakage of electricity from the cables.

The greatest PTFE-insulated electrical sleeves and other items on the market are made by our skilled professionals using the best raw materials and cutting-edge technology.

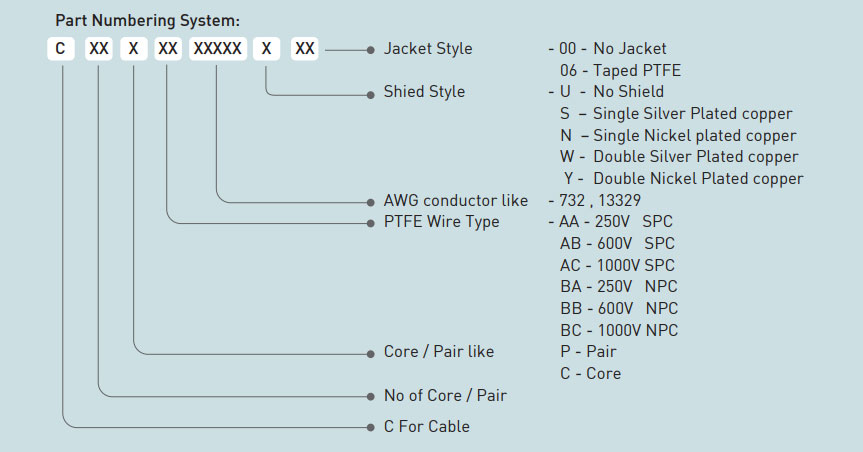

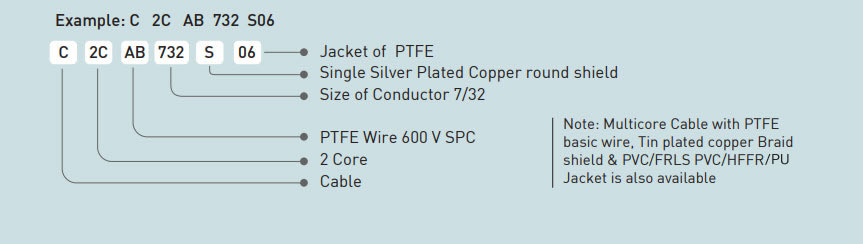

The part number system is as mention below. The part number specify the size, number of cores / pairs and type of Shield and Jacket.

Derating factor:

The following table used as a guideline for derating factor in multicore cables

| No of core | Derating factor (x Amps) |

|---|---|

| 2 - 5 | 0.8 |

| 6 – 15 | 0.7 |

| 16 - 30 | 0.5 |

Merits of PTFE Sleeve

Cables, hoses, and metal splashes are protected from blazing heat, fire, and flame by the PTFE Sleeve. To provide the cable mechanical strength and binding, certified PTFE wire is jacketed. To increase the cable's strength and durability, SS or GI wire braid armouring can be applied over the jacket. The entire cable can be shielded, each core can be individually insulated, or only a certain number of cores can be shielded while the remainder is left unshielded, depending on the situation. The wall thickness and sleeve diameter of the PTFE Sleeve are 0.25mm and 0.71mm, respectively. If you have any extra queries concerning the FUTEF's approved PTFE Wires, get in touch with our specialists!

- High performance from -200 °C to 260 °C, with a peak temperature of 300 °C.

- Autoclavable; unaffected by soldering temperatures.

- Smooth internals enables a closer fit, making them ideal for high-density wiring.

- You will have access to a top-notch tape-wrapping-sintering (TWS) process that offers long flex life, high burst pressure, and outstanding tear resistance in addition to good mechanical stability.

- FLU-TEF WIRES & CABLES PVT. LTD. PTFE Wires & Cables have a strong dielectric force, are UV radiation-resistant; unaffected by ageing, fungi, or water absorption and possess fire-resistance properties.

- With very few exceptions, inert to practically all chemicals, solvents, fluxes, and oils; fully biocompatible; and devoid of extractable.

- 100% checked, checks & tests against various stimuli accomplished.